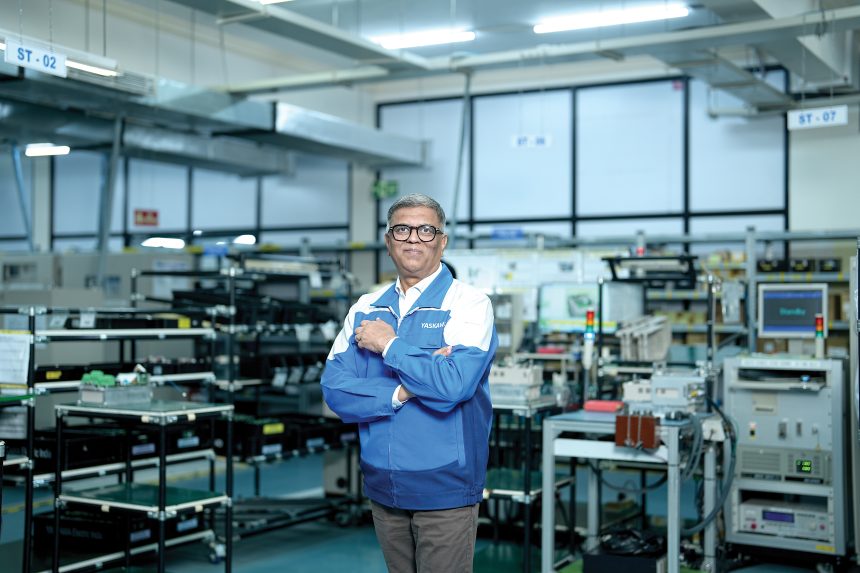

Shailendra Salvi, a leader in the industrial automation and robotics space and president and CEO of Yaskawa India Private Limited, a subsidiary of Yaskawa Electric Corporation, Japan, talks about India’s progress in robotics and what the next decade of intelligent technology might look like

Maria Fernandes | NT

What sparked your interest in automation and robotics and set you on this

career path?

During my electrical engineering studies at Goa College of Engineering, robotics was neither well known nor an established field. Growing up in Cansaulim in South Goa in the mid-1980s, our exposure to global technology was limited. Graduating as an engineer in 1988 itself was a major achievement. At that stage, my goal was not robotics specifically but to pursue something technically meaningful and different.

After graduation, I deliberately stepped outside Goa to broaden my perspective, beginning in the private cable industry and later working at Mormugao Port Trust. Experiencing both private and public sector environments strengthened my desire to grow technically. At college, learning was driven more by curiosity than grades, with a strong focus on fundamentals, particularly power electronics.

This foundation led me to ABB, where I worked on commissioning large industrial automation systems across industries. In 1996, ABB installed its first robot in our lab and that initial exposure to robotics made a lasting impression. Building on my automation experience, I later held leadership roles at Scandinavian firms such as Danfoss and Vacon and subsequently at Hitachi. My formal entry into robotics came in 2014, when Yaskawa established independent operations in India and I joined the organisation. It felt like a natural progression, bringing together years of experience in power electronics, automation, and industrial systems into a focused career in automation and robotics, a field that has since grown tremendously.

Building a career in an emerging technology space comes with unique challenges. What were some of the biggest setbacks you faced and how did they shape your professional growth?

Yes, there were challenges. A major turning point for me came when the global president and CEO of Yaskawa Japan asked me to lead both the robotics and automation divisions in India. This was a significant responsibility and required me to go much deeper into robotics, not just from a technical standpoint but also from a business perspective.

At that time, the robotics division was already substantial, with a large facility in Manesar. Leading it meant understanding the industry landscape, identifying growth opportunities, and building a sustainable business. One of the biggest challenges I faced was transitioning from being a technology leader to also becoming a business leader; balancing deep technical knowledge with market strategy and execution.

Initially, robotics adoption in India was largely limited to the automobile sector, especially among Japanese manufacturers such as Suzuki, Honda, and others, where Yaskawa robots were widely used for welding, painting, gluing and pick-and-place applications. While this segment was strong, it was clear that relying solely on automotive would restrict long-term growth.

The challenge, then, was how to expand robotics into new sectors. We made a conscious decision to focus on non-automotive industries, exploring applications in agriculture, cement, pharmaceuticals, food processing, skill development, and other critical segments.

As you transitioned from solving engineering problems yourself to leading teams, how did your views on people and

leadership change?

For me, the shift began with having a clear goal and a strong desire to grow. Coming from Goa, where exposure was limited, there was always a spark to reach beyond boundaries and move into leadership. Early in my career at ABB, I realised that in industries like automation and robotics, technical strength is non-negotiable. Most successful leaders in technology-driven fields are deeply grounded in engineering, and that realisation became a turning point for me.

As my technical confidence grew, my approach to leadership began to evolve. I understood that leadership in automation is not separate from technical expertise; it must be built on it. To strengthen this balance, I pursued formal learning, including programmes at the Scandinavian International Management Institute and an MBA from Great Lakes Institute of Management in Chennai. These experiences helped me develop management and strategic thinking alongside my technical foundation.

In my view, effective leadership in our industry is about being roughly 80% technical and 20% leadership skills. Without strong technical knowledge, it is difficult to earn respect. At the same time, leadership also requires being a good human being; having empathy, being decisive, staying grounded, and leading by example.

Even today, I remain closely connected to the field. I travel extensively, meet customers regularly, and maintain a transparent way of working within the company and with customers. In a highly competitive market alongside other global players, the ability to continuously learn, adapt, and lead with integrity is what truly defines a strong leader.

Over the past decade, how have you seen India’s manufacturing landscape transform in terms of robotics and automation? How would you describe where the Indian robotics sector stands today?

Over the past decade, India’s robotics ecosystem has reached a clear inflection point. Historically, industrial robots were used mainly in the automotive sector, which even today accounts for about 60–65% of robot deployments due to its need for precision, continuity and repeatability. Most robots are still imported, as India does not yet have large-scale robot manufacturing.

That said, the market is steadily expanding. Over the last three years, robotics adoption has grown at a CAGR of roughly seven–10%, with around 8,000 industrial robots sold annually. Yaskawa holds about 25% market share and the relatively small installed base underscores the significant untapped potential.

Globally, about 800,000 industrial robots are sold each year, nearly half of them in China. India accounts for only around one percent of global installations, highlighting both how early the market is and the scale of opportunity ahead.

Encouragingly, robotics adoption is now spreading beyond automobiles into sectors such as food processing, agriculture, pharmaceuticals, consumer goods and small-scale manufacturing. Companies are increasingly exploring robotics for applications like harvesting, sorting, packaging and material handling, even for fresh produce.

With advances in AI and vision systems, robots have become more flexible and easier to deploy. As a result, India’s robotics ecosystem is gradually becoming more diversified. While still at a nascent stage globally, the growing interest and demand suggest a phase of accelerated growth ahead.

Industry 4.0 is a term we hear a lot, can you explain what it encompasses? How does India compare to the rest of the world when it comes to robotics and smart

manufacturing?

Industry 4.0 is a concept originally introduced by Germany to describe the highest level of industrial automation. At its core, it refers to the integration of robotics, Artificial Intelligence and the Internet of Things (IoT), into a fully connected manufacturing ecosystem. In an Industry 4.0 environment, machines, sensors, motors, and controllers are all connected through IoT platforms, continuously generating and sharing data.

This data provides real-time insights into production performance, such as machine speed, temperature, energy usage, and maintenance needs, allowing manufacturers to optimise processes, improve efficiency, and predict failures before they occur. In essence, Industry 4.0 enables end-to-end automation, from production planning to execution and monitoring.

At Yaskawa, for example, we operate factories that function at Industry 4.0 levels. Through systems like the “Yaskawa Cockpit”, teams can monitor the entire manufacturing process, from robot assembly to motor and drive production, through a centralised digital interface.

In India, adoption of Industry 4.0 is progressing but still at an early stage. Certain sectors, such as pharmaceuticals and automotive manufacturing, have begun implementing elements of smart manufacturing and advanced automation. However, large-scale adoption remains limited due to high investment requirements and the need to modernise traditional manufacturing practices. Many existing systems, motors, sensors, controllers, must be upgraded to be IoT-enabled, which requires both capital and technical readiness.

Globally, countries like China and Germany have made significant progress in automotive manufacturing, while Japan has advanced in both automotive and pharmaceutical automation. Industries such as semiconductors and electronics manufacturing worldwide are also rapidly moving toward Industry 4.0 standards.

In India, only an estimated four to five percent of manufacturing has currently reached true Industry 4.0 levels. While the potential is enormous, achieving wider adoption will require sustained investment, infrastructure upgrades, and a shift in mindset toward data-driven, connected manufacturing.

We’re seeing robots being used across a much wider range of industries. Are there any particularly unique or innovative applications of robotics today that stand out to you?

There are many fascinating applications of robotics today. In Japan, for example, robots are used in bento box production to fill compartments like rice, vegetables, and curry with precision. At our own facilities, we have a robot that prepares and serves udon noodles; cooking, adding soup and serving it entirely autonomously.

In manufacturing, Industry 4.0 has enabled fully automated production lines, where robots even assemble other robots. Collaborative robots or cobots, now work alongside humans, learning tasks like welding or assembly and repeating them with high accuracy. Robots are also widely used in areas like automobile painting, with advanced vision systems ensuring perfect quality.

As automation expands and scales, digital tools are becoming essential. Which technologies are making an impact on robotics adoption more efficient?

Robotics is a key component of Industry 4.0 and digitalisation plays a crucial role in enhancing both quality and productivity. Today, investing in robotics has become far more practical because the economics of scale have improved. Earlier, robots were often seen as expensive and risky but now companies carefully evaluate ROI, space requirements, process consistency, safety and quality before making decisions, whether for new factories or retrofitting existing ones.

We are seeing robotics applied across a range of industries in ways that improve efficiency and protect workers. In sugar plants, for instance, robots can handle heavy bags, picking them from conveyors and loading them into trucks, reducing manual labor while maintaining speed and consistency. In the cement industry, robots equipped with suction systems can lift multiple bags at once, minimising exposure to hazards such as dust. In automotive manufacturing, robots are widely used for welding and painting, tasks that involve fumes and gases harmful to humans. Not only does this enhance worker safety, but it also ensures uniform quality and precision.

Overall, the technologies driving robotics adoption today focus on combining automation with digital monitoring, process optimisation and safety, allowing industries to operate more efficiently while safeguarding human health.

Which AI trends do you think will have the biggest impact on the future of robotics, both in India and globally?

Artificial Intelligence in robotics depends on data, the more a robot can process, the smarter it becomes. That’s why sensing technologies like vision, touch and motion are critical. Vision systems let robots ‘see’ and track objects, while touch and motion sensors enable human-like interaction, improving precision and adaptability.

AI builds on this by interpreting sensor data, allowing robots to recognise objects, detect anomalies, and make real-time decisions. The future of robotics, both in India and globally, will be driven by AI that enables robots to sense, perceive and respond intelligently, mimicking human capabilities in advanced industrial and service applications.

What skills do you think the next generation of robotics and AI engineers will need and will be most critical?

Today, in engineering, you often hear the term ‘mechatronics’, which combines mechanical, electrical, electronic and IT concepts. Yaskawa originally coined and registered this term as a trademark in the 70s. While mechatronics is now a formal part of education, having a solid foundation in basic electrical and electronics is sufficient to become an expert in robotics.

What truly matters is seriousness, curiosity and the ability to apply fundamental concepts to solve real-world problems. Strong fundamentals are critical for anyone pursuing robotics or advanced technologies.

Our government and educational institutions are increasingly supporting skill development. Robotics, 3D printing, EVs and laser cutting are becoming accessible even at school levels. For example, technical education is now introduced as early as the eighth grade, including exposure to robotics. This shift is transforming mindsets; not just of students but also teachers, parents and the broader society, helping create a skilled workforce in India. I see this change firsthand when I visit schools like my alma mater, St. Thomas High School in Cansaulim, for CSR activities. The students and teachers today are highly knowledgeable and globally competitive, which is a huge leap from when I studied there.

There is a lot of discussion around jobs and robotics. In your view, does robotics in India create new opportunities, reshape existing ones or both?

Every individual needs to focus on upskilling, no matter what work they do. If someone just goes through the motions and doesn’t enjoy what they’re doing, it’s hard to bring about real change. Upskilling is essential because at the end of the day, humans are the ones controlling robots, AI, IoT systems and Industry 4.0 technologies, all of which we have developed. Robots are not here to take our jobs; they are here to make processes faster, safer and more precise and to handle tasks that can be hazardous, like exposure to fumes or harmful materials.

For talented engineers, this is a tremendous opportunity. It’s a chance to look beyond routine work and apply creativity and innovation to leverage today’s technologies in new ways. When I graduated, we didn’t even know what a robot was. Today, young engineers have the opportunity to work in world-class companies like Yaskawa, the largest robotics company globally. If I were in their position, I would seize the opportunity to experiment, programme, and create new solutions.

I always tell young professionals, especially those from Goa, that coming to Bengaluru to work here is not just about doing a nine-to-five job. You should bring your ideas, your curiosity and your initiative. Step forward, propose something different and take ownership, because that’s how talent grows and that’s how we advance the industry in India.

While robotics and AI are advancing rapidly, human expertise remains central. These technologies don’t replace people, they complement us, requiring new skills and enabling higher productivity, consistency, and quality across industries.

Looking ahead, a decade down the line, what would success look like for robotics and AI in India? What advice would you give to professionals or manufacturers who are still hesitant about Industry 4.0?

If we look at India today, the installed base of industrial robots is still very small, around 80,000 units and most of these are in the automobile sector. Outside of automobiles, robotics adoption is still in its infancy but the potential is enormous. Robots are already being used for pick-and-place tasks, agriculture, cement, brick-making and even construction. I’ve seen robots that build walls and apply plaster and others that can clean toilets in airports. In Japan, for example, automated guided vehicles transport trays across factories and restaurants even use robots to deliver food, these examples show the breadth of possibilities.

India has an incredible pool of talent, from IT to engineering and we also have the creativity to innovate. But the challenges remain, sustaining high quality, competing with international cost pressures and establishing local manufacturing capabilities.

For professionals and manufacturers hesitant about Industry 4.0, my advice is to embrace it as an opportunity rather than a threat. Robotics and AI are tools that improve speed, precision, productivity, safety and efficiency. If we combine innovation, technical skill and strong leadership, India has the potential to become a global hub for automation. At Yaskawa, we’re already looking ahead with our Vision 2035 and India has been recognised as the strongest pillar globally. The future of robotics, automation and Industry 4.0 in India is not just promising, it’s transformative.